gần đây bài viết

Pearlescent pigments are effect pigments that give a soft or shimmering pearlescent sheen to product surfaces. As one of China's top 10 pearlescent pigment exporters, Anhui iSuoChem, with its extensive technical expertise and export experience in the field, has become the preferred partner for the global coatings, plastics, inks, and cosmetics industries.

This article will delve into the core characteristics of pearlescent pigments in different application systems, helping you achieve more perfect visual effects in product development.

Characteristics of pearlescent pigments in different application systems

Pearlescent pigments are most widely used in automotive paints, architectural coatings, and industrial coatings.

Weather Resistance and Physical Stability: iSuoChem's pearlescent pigments are coated with rutile titanium dioxide, exhibiting excellent lightfastness and chemical resistance.

Orientation: Pearlescent pigments have a plate-like structure. During spraying, the pigments must be oriented parallel to the substrate to produce the best "angle-dependent color" effect.

Dispersibility: Pearlescent pigments are inorganic pigments and tend to settle in low-viscosity systems. It is recommended to add rheology modifiers (such as fumed silica or bentonite) to the formulation to prevent precipitation.

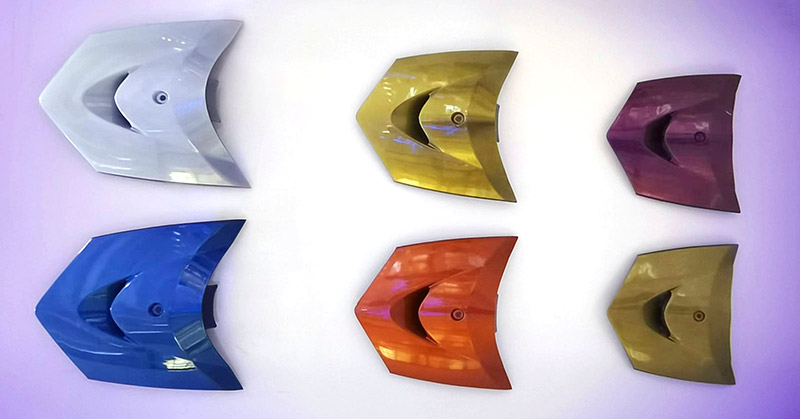

Pic# Pearl pigment powder for metal coatings

In injection molding, blow molding, and masterbatch processing, pearlescent pigments impart a silky sheen to plastic products.

High Temperature Resistance: Pearl pigments can typically withstand temperatures above 800°C, making them fully compatible with the processing of various thermoplastics.

Shear Sensitivity: The lamellar structure of pearlescent pigments is easily broken under excessive mechanical shear, resulting in damaged gloss. It is recommended to minimize high-shear time during processing or to add pigment at the end of the process.

Addition Ratio: A typical addition ratio is recommended between 0.5% and 2%; however, in masterbatches, the concentration can be as high as 20% to 30%.

Pearlescent pigments perform exceptionally well in flexographic, gravure, and screen printing. • Particle Size Selection: This is crucial for the printing system. Higher network density requires finer pigment particle sizes.

Fine Particle Size (5-25µm): Good hiding power, soft gloss, suitable for fine text printing.

Coarse Particle Size (10-60µm+): High shimmer, strong transparency, suitable for large-area backgrounds.

Chemical Neutralization: Pearl pigments are non-conductive and chemically inert, and will not react with ink base materials.

Pic# Pearl pigment powder for leather

Purity and Safety: iSuoChem's cosmetic-grade mica powder strictly adheres to international heavy metal standards (FDA/EU).

Skin-Friendliness: Synthetic mica has higher whiteness and purity than natural mica, and a smoother feel, often used in high-end eyeshadows and lipsticks.

Light Diffusion Effect: Utilizing the refraction and reflection of light, pearlescent pigments can effectively conceal fine lines on the skin, enhancing the translucency of makeup.

System

Properties

Water-based System

• Good dispersibility, easy to mix with water

Solvent-based System

• Excellent dispersibility and stability

Plastic System

• Good thermal stability, resistant to high temperatures

Coating System

• Provides unique metallic luster and color effects

Cosmetic System

• Safe and non-toxic, meets cosmetic standards

Printing Ink System

• Good fluidity and printability

• Environmentally friendly, low VOC emissions

• Relatively slow drying speed

• Suitable for interior coatings and printing inks

• Moderate water and chemical resistance

• Fast drying, high gloss

• Good weather resistance and durability

• Suitable for automotive coatings and industrial coatings

• High VOC content, requires good ventilation

• Excellent dispersibility and color uniformity

• Good compatibility with various plastic resins

• Suitable for injection molding, extrusion and other processing techniques

• Does not affect the mechanical properties of plastics

• Good weather resistance and UV stability

• Compatible with various resin systems

• Suitable for decorative coatings and industrial coatings

• Enhances visual appeal and added value of coatings

• Provides shiny and pearlescent effects

• Good skin adhesion and stability

• Suitable for eyeshadow, lipstick, nail polish, etc.

• Bright colors, enhances product aesthetics

• High color strength and gloss

• Suitable for various printing processes (gravure, screen printing, etc.)

• Fast drying speed, good adhesion

• Enhances visual texture and grade of printed materials

© 2023 Pearlescent Pigment Properties Study

Data is for reference only, actual application should be adjusted according to specific products and technical conditions

Besides the application characteristics mentioned above, what specific characteristics do pearlescent pigments have when applied to resin systems or solvent systems?

|

Resin & Solvent |

Wetting |

Dispersity |

Feature of wetting and dispersity |

|

Polyester Resin Phenolic resin Hydroxy acrylic resin N-butylated melamine-formaldehyde resin Nitro cellulose resin Alkyd Resin Bisphenol A epoxy resin Aromatic isocyanate Aliphatic polyisocyanate |

Excellent Good Excellent Excellent Bad Excellent Good Bad Bad |

Excellent Good Excellent Excellent Bad Excellent Good Bad Bad |

Increaseing with Hydroxyl value Etherification &rosin modified will be better Thermoset is better than thermoplastic Increasing with etherification value It will be better to mix with other resin Increasing with long oil degree Increasing with epoxide equivalent Increasing if adding DNF Increasing if adding DNF |

|

Varsol Esters solvent Alcohols solvent Ketones solvent DMF Isophorone |

Bad Excellent Excellent Excellent Best Best |

Bad Excellent Excellent Excellent Best Best |

Aliphatic hydrocarbon solvent is better Acetate solvent are all good polyhydric alcohol is better isophorone is best Can be cosolvent Can be cosolvent |

As one of China's top ten pearlescent pigment suppliers, iSuoChem not only provides products but also offers comprehensive application technical support.

Features & Advantages

Brand Position

Top 10 Pearl pigment supplier in China, possessing a complete industry chain.

Core Pearlescent Products

Covers natural mica, synthetic mica, and glass-based pearlescent pigments.

R&D Strength

Focuses on the research and development of weather resistance, anti-yellowing, and ultra-bright pearlescent effects.

Applications

Inks, Automotive coatings, industrial coatings, high-end plastics, and cosmetics.

Pic# Pearl pigment for cosmetics

In the market environment of 2026, the application of pearlescent pigments is developing towards environmental friendliness (solvent-free system compatibility) and functionalization (thermal insulation, conductivity). If you are looking for high-quality, cost-effective pearlescent pigments, iSuoChem's professional team will tailor a solution for you.

Experts advise that when selecting pearlescent pigments, it is essential to consider the refractive index of the carrier system. The greater the difference in refractive index between the pigment and the substrate, the more pronounced the pearlescent effect.

Need a sample for your next project? Contact iSuoChem, a top 10 China supplier, for expert guidance.

thẻ :

đội ngũ chuyên nghiệp để phục vụ !